The Bamboo Fusion Workshop was an intensive design–build programme that explored how traditional materials can be reimagined through advanced digital tools. Hosted in Suzhou in 2025, the workshop brought together 20 international participants, who, over the course of five days, designed and constructed a full-scale pavilion measuring 5.3 × 4.2 × 2.9 metres.

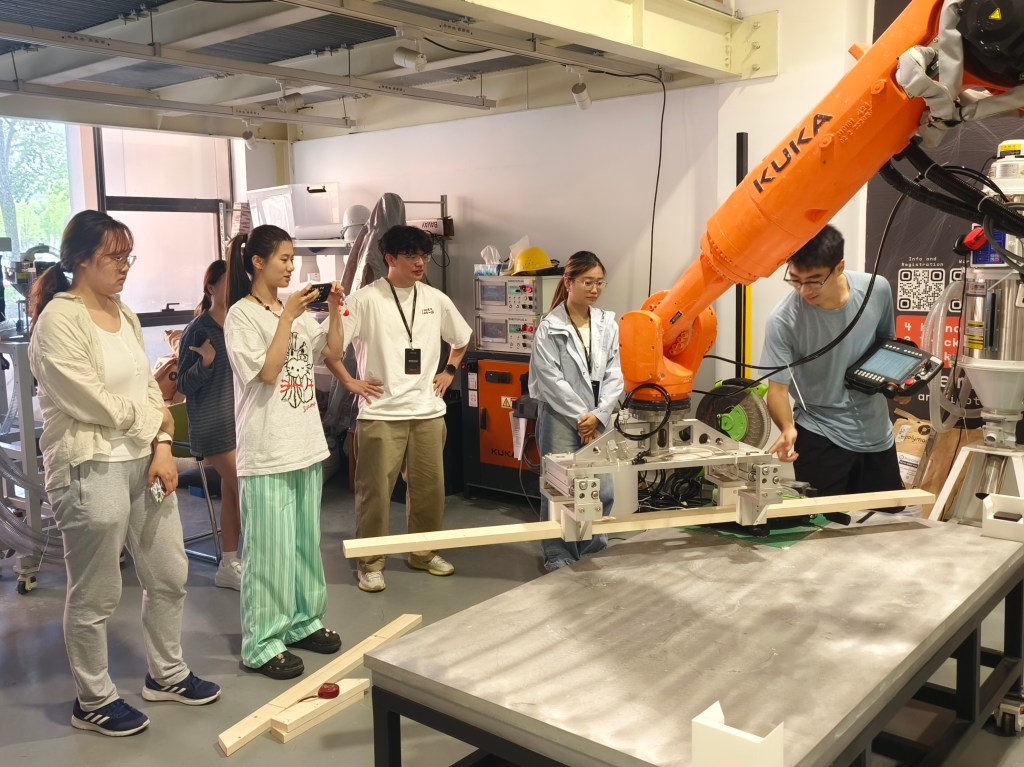

At the heart of the workshop was a hybrid construction system combining nine planar timber frames as the primary structure, thirty-four secondary members to stabilise the frame and provide fixing points, and twenty-seven woven bamboo cladding panels mounted on trapezoidal or parallelogram timber frames. These elements were fabricated through a workflow that integrated parametric modelling, robotic cutting, and augmented reality (AR)–assisted assembly.

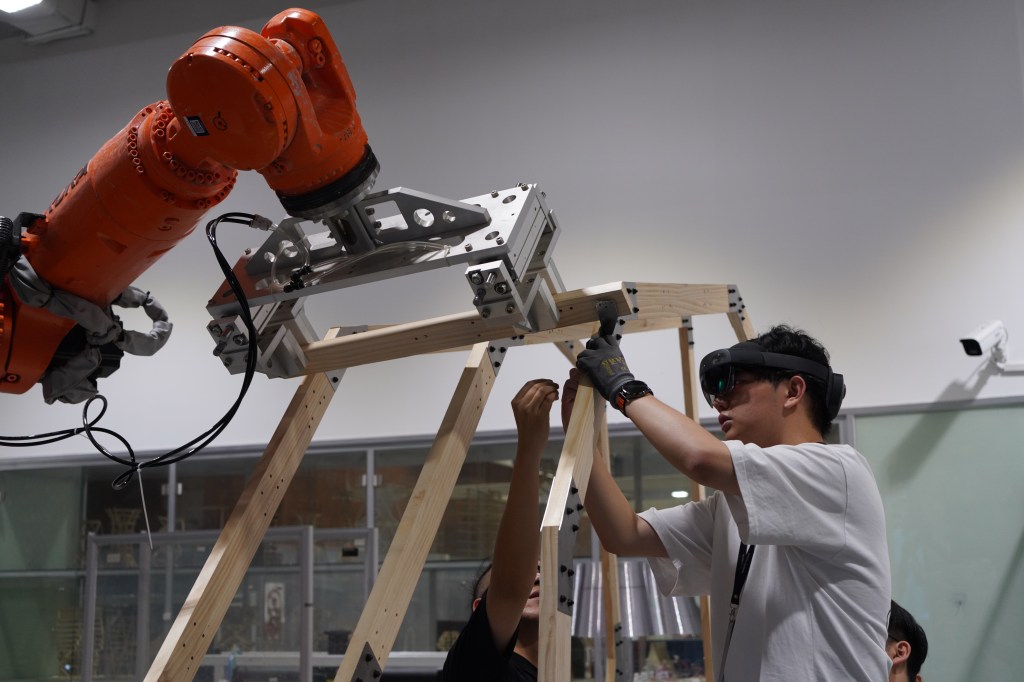

Parametric tools were used to optimise geometry and anticipate material behaviour, while a robotic arm executed precise non-orthogonal timber cuts. AR overlays, viewed through Microsoft HoloLens headsets, guided participants step by step, projecting holographic targets for positioning and assembly. This allowed non-experts to accurately align and assemble components, demonstrating how digital augmentation can lower the expertise threshold in construction.

The final pavilion highlighted the synergy between rigidity and flexibility, structure and skin, with timber and bamboo contributing lightness and tactility. Despite minor challenges in manual labelling and panel matching, the project achieved tighter tolerances and shorter build time compared to previous workshops.

Bamboo Fusion demonstrates the potential of AR to enhance efficiency and accuracy while preserving the value of craft, pointing toward future workflows where digital detailing and material intelligence are productively aligned.

Leave a comment